Drying Washed Coffee Beans: Fluidized Bed Dryer vs. Rotary Kiln Dryer

When drying washed coffee beans, choosing between a fluidized bed dryer and a rotary kiln dryer requires balancing factors such as drying efficiency, quality control, and cost. Below is a comparative analysis and recommendations:

—

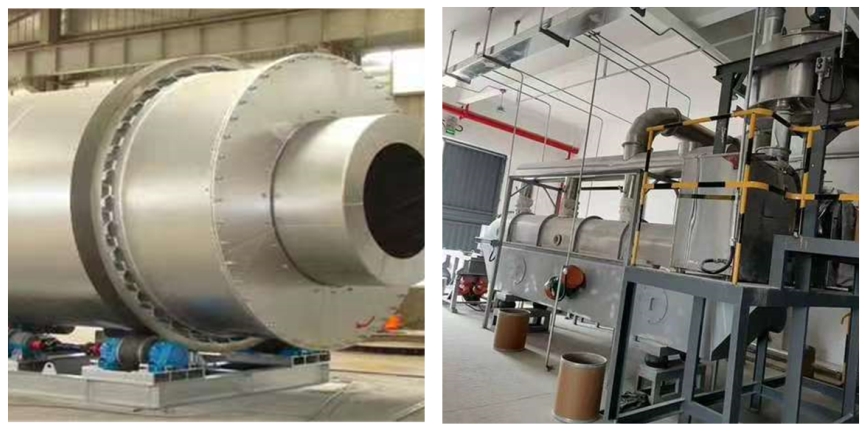

- Fluidized Bed Dryer

Advantages:

– Rapid drying speed: Hot air directly contacts the beans, rapidly removing moisture, ideal for large-scale continuous production.

– High uniformity: Suspended particles ensure even heat distribution, reducing risks of localized overdrying or mold.

– Precise temperature control: Suitable for temperature-sensitive materials; airflow adjustments prevent flavor degradation.

Disadvantages:

– Physical damage risk: High-speed airflow may cause bean collisions or surface abrasion, affecting appearance and storage stability.

– High energy consumption: Maintaining fluidization increases operational costs.

– High initial investment: Complex equipment, better suited for high-volume production.

—

- Rotary Kiln Dryer

Advantages:

– Gentle drying process: Low-temperature, slow dehydration preserves aromatic compounds, ideal for high-quality beans.

– Low mechanical damage: Gentle tumbling minimizes bean breakage.

– Adaptability: Handles beans with varying moisture levels or sizes, offering operational flexibility.

Disadvantages:

– Long drying time: Prolonged processing may increase microbial contamination risks (e.g., mold), requiring strict environmental monitoring.

– Energy inefficiency: Extended operation accumulates energy costs, especially for small-scale production.

– Uniformity challenges: Overloading or improper rotation speed can lead to uneven drying.

—

- Key Requirements for Washed Coffee Beans

– Moisture control: Requires reducing moisture from ~50% to 10–12%, with temperatures ideally below 35–40°C to avoid flavor loss.

– Quality focus: Washed beans are often used for specialty coffee, demanding strict flavor and bean integrity standards.

—

- Recommendations

– Prioritize rotary kilns:

For medium-scale production or flavor-critical applications (e.g., premium beans), rotary kilns’ gentle drying is preferable. Optimize rotation speed and loading to ensure uniformity.

– Fluidized bed use cases:

Suitable for high-efficiency, large-scale operations with precise temperature control (e.g., smart systems). Test bean durability to avoid mechanical damage.

– Hybrid drying strategy:

Combine both technologies: use fluidized beds for rapid initial drying and rotary kilns for final low-temperature curing to balance speed and quality.

—

- Practical Examples

– Specialty coffee producers: Often use rotary kilns or traditional sun-drying to emphasize flavor complexity.

– Large-scale facilities: Favor fluidized beds for efficiency, e.g., some Brazilian farms use them for commercial-grade beans.

—

Conclusion: Drying washed coffee beans involves trade-offs between quality and efficiency. For flavor-centric production, rotary kilns are recommended; for high-throughput operations with technical precision, fluidized beds are viable. Final decisions should involve equipment testing and cost-benefit analysis.