The coffee bean processing refers to the steps of extracting beans from coffee cherries (the fruit) and preparing them for roasting. This process directly impacts the coffee’s flavor, acidity, sweetness, and mouthfeel.

Below are the common steps and primary methods of coffee bean processing:

1. Harvesting- Ripeness Selection:

Coffee cherries are hand-picked at peak ripeness (typically red or yellow) to ensure optimal flavor.

Sorting: Removal of unripe, overripe, or damaged cherries.

If you are using mechanical picking and a large number of green and red coffee cherries are mixed together, you can use our coffee cherry color sorters for sorting.

2. Processing Methods

The core of processing is removing the fruit pulp and mucilage while preserving bean quality. Three primary methods are:

(1) Washed (Wet Process)

Depulping: Machines remove the outer skin and most of the pulp.

Fermentation: Beans with mucilage are soaked in water tanks for 12–72 hours, allowing microbes to break down remaining mucilage.

Washing & Drying: Rinsed with water, then sun-dried or machine-dried to 10–12% moisture content.

Hulling: hulling the chaff which around the coffee bean .

Characteristics:

Flavor: Bright acidity, clean taste, emphasizes the bean’s “pure” profile.

Pros: Consistent quality, lower risk of mold.

Cons: High water usage, costly.

-959x1024.jpg)

2) Natural (Dry Process)

Sun-Drying: Whole cherries are spread on drying beds or patios for 2–4 weeks, regularly turned.

Hulling: Machines remove the dried husk and pulp after drying.

Characteristics:

Flavor: Fruity, pronounced sweetness, possible fermented notes.

Pros: Water-efficient, ideal for arid regions.

Cons: Weather-dependent, risk of contamination or over-fermentation.

3) Honey (Pulped Natural Process)

Partial Depulping: Skin and some pulp are removed, leaving varying amounts of mucilage (classified as white, yellow, red, or black honey).

Drying: Beans are dried with mucilage intact.

Characteristics:

Flavor: Balanced sweetness and acidity, often with honey or caramel notes.

Pros: Lower water use, complex flavors.

Cons: Requires precise drying control.

3. Drying

– Critical for all methods, reducing moisture to 10–12%.

Sun-Drying: Uses sunlight and airflow, slower (1–4 weeks).

Mechanical Drying: Faster with machines but costlier.

4. Hulling & Polishing

Hulling: Machines remove the parchment layer.

Polishing (optional): Removes silver skin for smoother beans (may affect flavor).

Hulling method of washed beans and sundried beans are different, refer to preceding part Step 2 Processing method.

5. Grading & Sorting

Size Grading: Sieves sort beans by size (e.g., AA, AB grades).

Color Sorting: Manual or mechanical removal of defects (blackened, insect-damaged beans).

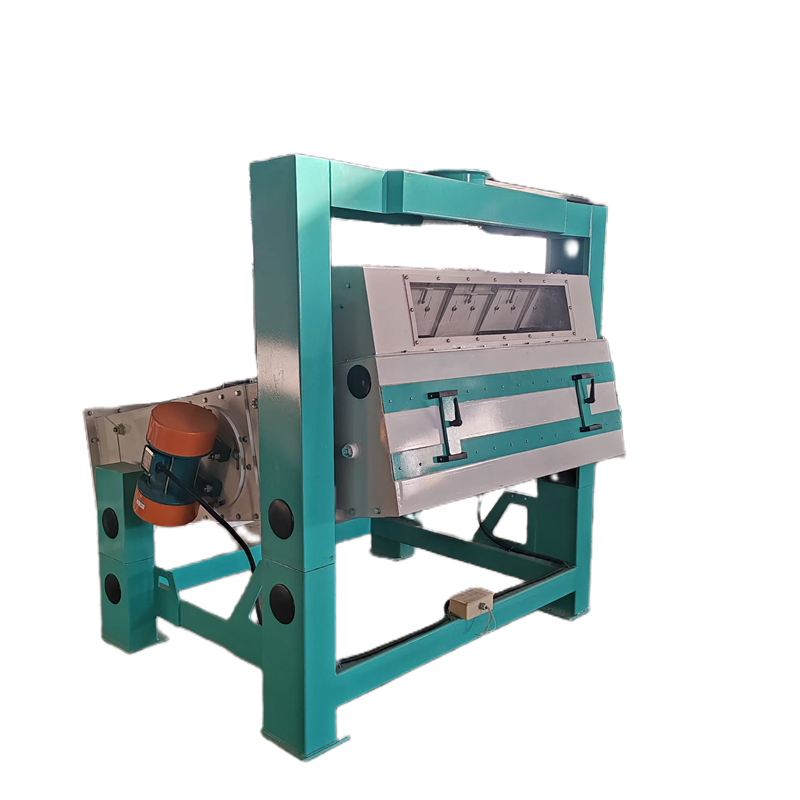

We have a machine called the Coffee Bean Size Sorter, also known as a vibrating screen. It has two layers of screens. Through vibration, smaller coffee beans will fall to the lower layer, larger coffee beans remain on the upper layer, and broken beans and dust are screened out at the bottom.

Coffee bean color sorter can sort coffee beans according to colors. It’s faster and more accurate than manual sorting. It intelligently calculate and analyze the colors and shapes of both qualified products and defective ones. Bad beans that don’t match the preset colors, as well as those with non – standard shapes, will be sorted out.

6. Storage & Shipping

– Green beans are stored in dark, dry, temperature-controlled environments, often in jute sacks or vacuum-sealed bags.

– Protected from moisture and heat during transport.

7. Roasting

– Green beans are roasted (180–250°C) at their destination, triggering Maillard reactions to develop aroma and flavor.

Summary

Coffee processing defines flavor profiles: washed highlights acidity, natural emphasizes sweetness, and honey offers balance. Innovative methods (e.g., anaerobic fermentation) continue to expand coffee’s flavor possibilities.