Drum Coffee Roasters: A Deep Dive into Their Strengths and Limitations

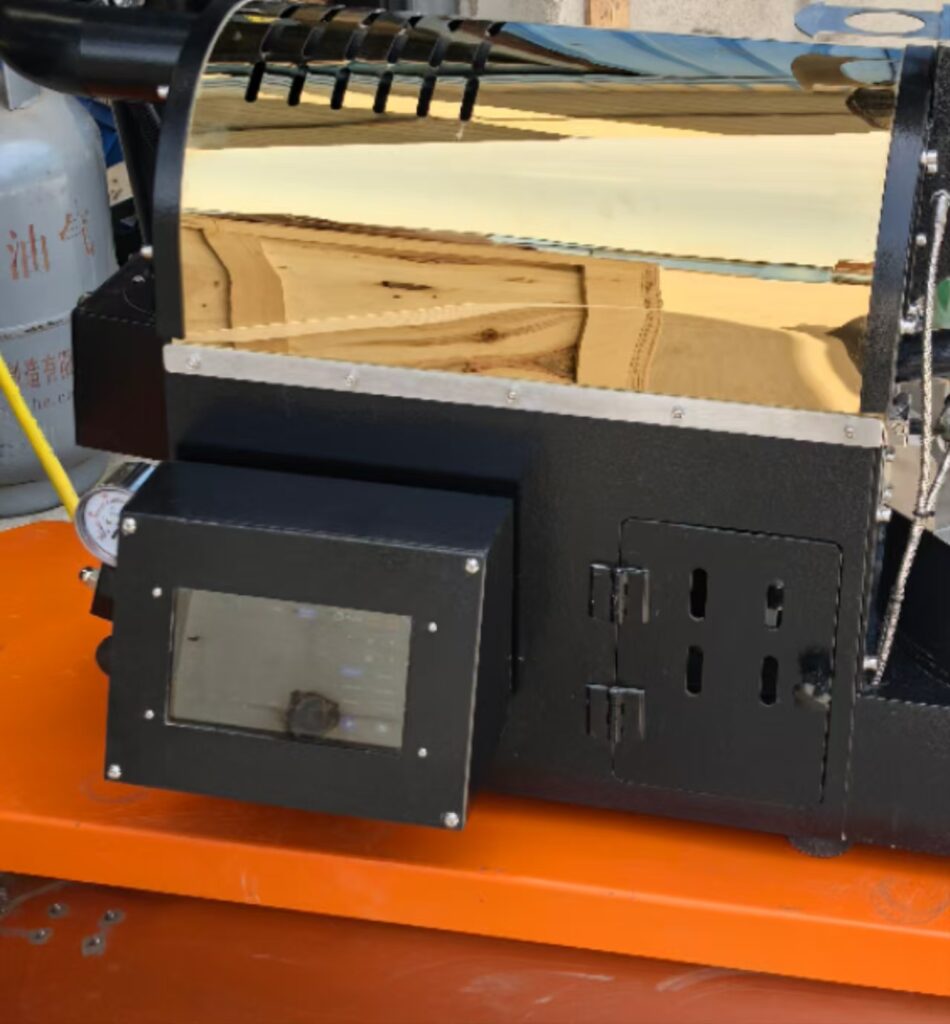

Drum coffee roasters have long been a staple in both commercial and home coffee roasting, valued for their ability to produce rich, complex flavors. These machines operate by rotating a cylindrical drum over a heat source, allowing coffee beans to tumble and absorb heat through conduction and convection. Below, we explore the key advantages and challenges of drum roasters, helping you decide if they align with your roasting goals.

Core Advantages of Drum Roasters

1. Precise Heat Control and Flavor Development

Drum roasters excel at delivering consistent heat distribution, which is critical for developing nuanced flavors. The rotating drum ensures beans are exposed to heat evenly, reducing the risk of scorching or underdevelopment. Advanced models feature digital temperature controls and adjustable drum speeds, enabling roasters to fine-tune profiles for light, medium, or dark roasts. This precision is particularly beneficial for specialty coffee roasters aiming to highlight regional characteristics or experimental processing methods.

2. Versatility Across Roast Levels

From delicate light roasts with bright acidity to bold dark roasts with caramelized sweetness, drum roasters adapt well to diverse preferences. The ability to modulate drum speed and heat intensity allows roasters to emphasize specific flavor notes, such as fruity undertones in African beans or chocolatey depth in South American varieties. This flexibility makes drum roasters ideal for small-batch producers or cafés offering seasonal coffee menus.

3. Durable Construction and Longevity

Built with heavy-duty materials like stainless steel or cast iron, drum roasters are designed to withstand frequent use. Their robust construction minimizes wear and tear, even when processing large batches. Additionally, many models include replaceable parts (e.g., bearings, seals) to extend their lifespan, making them a cost-effective investment for serious roasters.

Common Challenges with Drum Roasters

1. Risk of Uneven Roasting Due to Drum Dynamics

While drum roasters generally promote even heating, improper setup can lead to inconsistencies. For example, excessive drum speed may cause beans to cling to the walls, absorbing too much heat and burning. Conversely, insufficient speed can result in uneven tumbling, leaving some beans underroasted. Achieving optimal drum rotation requires calibration and practice, which may deter beginners.

2. Potential for Chaff Accumulation and Fire Hazards

As beans roast, they shed a papery husk called chaff. In drum roasters, chaff can accumulate in crevices or exhaust systems, posing a fire risk if not cleaned regularly. Some models include chaff collectors, but these require frequent emptying. Roasters must also monitor airflow to prevent chaff from igniting, adding a layer of operational complexity.

3. Energy Inefficiency Compared to Modern Alternatives

Traditional drum roasters rely on direct heat transfer, which can be less energy-efficient than hot-air or fluid-bed systems. The need to preheat the drum and maintain consistent temperatures throughout the roast consumes significant fuel or electricity. While newer models incorporate insulation and heat-recovery systems, energy costs remain a consideration for high-volume operations.

Operational Considerations for Optimal Results

Balancing Drum Speed and Heat Input

The interplay between drum speed and heat intensity is critical. Faster rotation distributes heat more evenly but may reduce contact time with the drum wall, slowing heat absorption. Slower rotation increases conduction but risks uneven tumbling. Roasters often start with manufacturer recommendations and adjust based on bean density, moisture content, and desired roast profile.

Managing Chaff and Exhaust Systems

To mitigate chaff-related risks, roasters should:

- Install high-efficiency chaff collectors.

- Schedule regular cleaning of drums, exhaust ducts, and cooling trays.

- Use airflow controls to maintain consistent exhaust velocity, preventing chaff buildup.

Monitoring Roast Development

Drum roasters require active supervision, especially during critical phases like the “first crack” (when beans release steam and expand) and “second crack” (indicating darker roasts). Roasters use temperature probes and visual cues (e.g., bean color, aroma) to time adjustments. Automated systems with pre-programmed profiles can simplify this process but may limit creative experimentation.

Drum coffee roasters remain a popular choice for their ability to produce rich, layered flavors and adapt to various roast styles. However, their success hinges on proper calibration, maintenance, and operational vigilance. By understanding their strengths and limitations, roasters can leverage drum machines to craft coffees with distinct regional identities or innovative flavor profiles, ensuring a memorable cup for enthusiasts and connoisseurs alike.